An Industrial Shredder is a machine utilized for decreasing the size of a wide range of materials. It is a machine or gear utilized for destroying. Destroying frameworks is used to diminish the size of a given material. While most web-based word references characterize the shredder as “a gadget utilized for destroying records as a safety effort to forestall wholesale fraud,” shredders can be of many sorts given the material being handled. Most shredders are intended to help decrease material.

A granulator sets up an Industrial Shredder; this shredder decreases the size of the handled material.

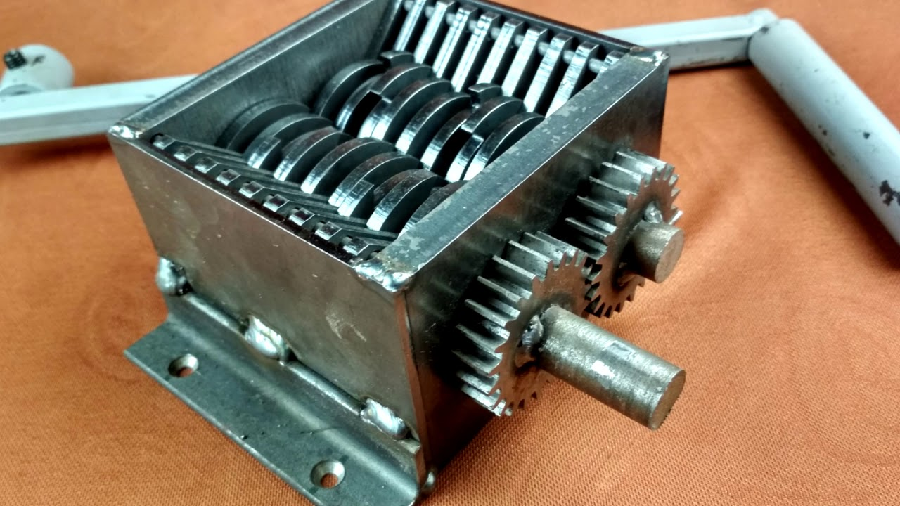

The fundamental classifications of today’s plans are as follows: even hammer mills and vertical hammer mills. Slow speed shear type shredders of single, double, triple, and quad shaft configuration; single shaft processors of single or double shaft plan, translators, blade pigs. Rappers maulers thrash saltine factories and refining plants. Modern shredder parts incorporate a rotor, counter, sharp edges, lodging, engine, transmission, power, and electrical control.

A few instances of regularly destroyed materials are tires, metals, car crashes, wood, plastics, cowhides, papers, and trash. It is ordinarily used to deal with materials of various sizes for partitions or to decrease the expense of transport. Squander materials like strong city waste, radioactive waste, clinical waste, and risky waste are destroyed in treatment and removal frameworks.

Since the hardness of materials varies, the edges on shredders are additionally marginally unique.

An Industrial Shredder is any shredder that can be utilized in a modern application (instead of a buyer application). They can be furnished with various cutting frameworks: level shaft plan, vertical shaft configuration, single-shaft, two-shaft, three-shaft, and four-shaft cutting frameworks. These shredders are slow speed or high velocity and are not confined in that frame of mind as modern shredders by their speed or drive. Little, minimal expense compact shredders have been created; these are frequently appropriate for individual use concerning limited scope businesses.

The most giant salvaged material shredder on the planet was planned with 10,000 hp by the Schnitzer steel gathering in Portland, Oregon, in 1980. The 9,200 hp (6,860 kW) Lynxs at the Sims Metal Management plant at the mouth of the River Usk in Newport, Wales, approached by street, rail, and ocean. It can handle 450 vehicles each hour.